What Does S and L Mean On A Door Closer?

If you have ever tried to adjust a commercial door closer you may have noticed two hex key screws on the side of the door closer labeled "S" and "L". In this article we explain what the "S" and "L" stand for, their function, how they are used on door closers.

On the side of a standard door closer body are two hex key screws, one with the letter "S" above it, and the other with the letter "L" above it. Although they appear to be a hex key type of screws, they actually function as valves to regulate hydraulic fluid from one chamber within the door closer body to another chamber within the door closer body.

![]()

The illustration above shows the "S" and "L" valves removed from the door closer body. The valve is threaded and designed to be turned clockwise to restrict the flow of hydraulic fluid, or counterclockwise to increase the flow of hydraulic fluid. On the valve are o-ring seals which are needed to ensure that the closer body remains sealed since it holds the hydraulic fluid. O-ring seals are also used to ensure air does not get into the closer body which could create problems when the hydraulic fluid is put under pressure. For these reasons, the "S" and "L" valves are not designed to be completely unscrewed and removed. Doing so, will cause the door closer to lose hydraulic pressure, and will ruin the door closer. In fact, if the "S" and "L" valve are adjusted it is best to only do a 1/8 to 1/4 turn at a time.

![]()

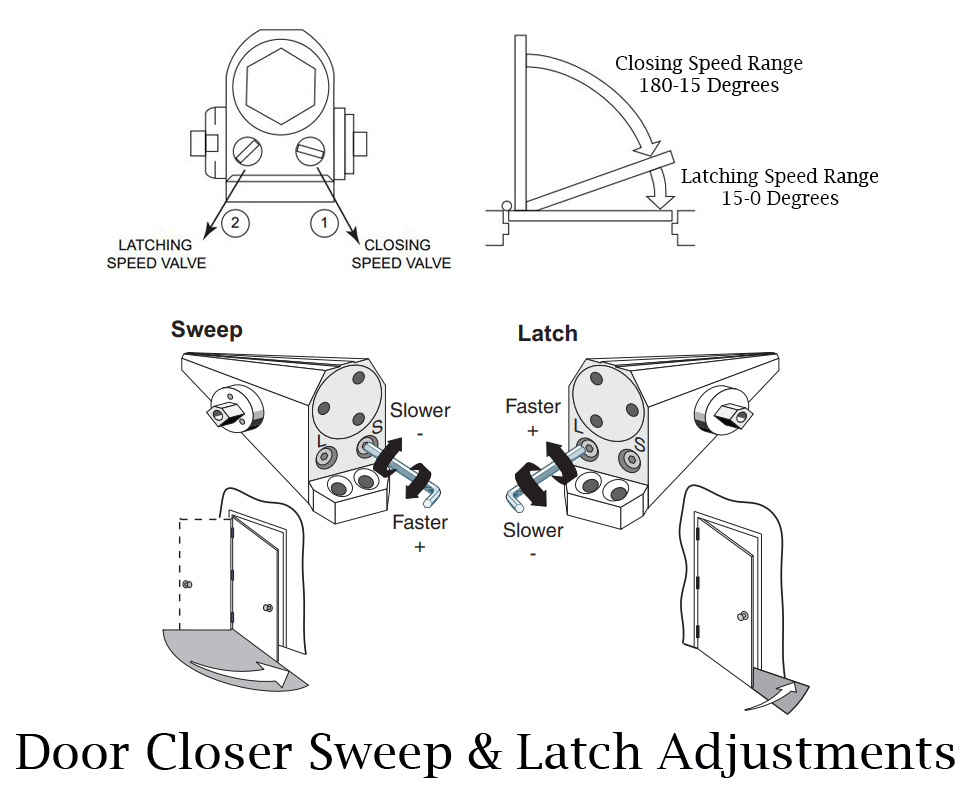

"S" Stands For "Sweep"

The "S" valve on the side of the door closer body stands for "sweep". The illustration above shows a door's closing cycle. The sweep refers to the portion of the closing cycle from the 180 degree full open position to approximately 15 degrees of the closing cycle. The sweep valve adjusts the closing speed of the door during the sweep range.

"L" Stands For "Latch"

The "L" valve on the side of the door closer stands for "latch". On the illustration above the portion of the door closing cycle from approximately 15 degrees to 0 degrees is the the latch range of the closing cycle. The latch valve adjusts the closing speed of the door during the latch range.

![]()

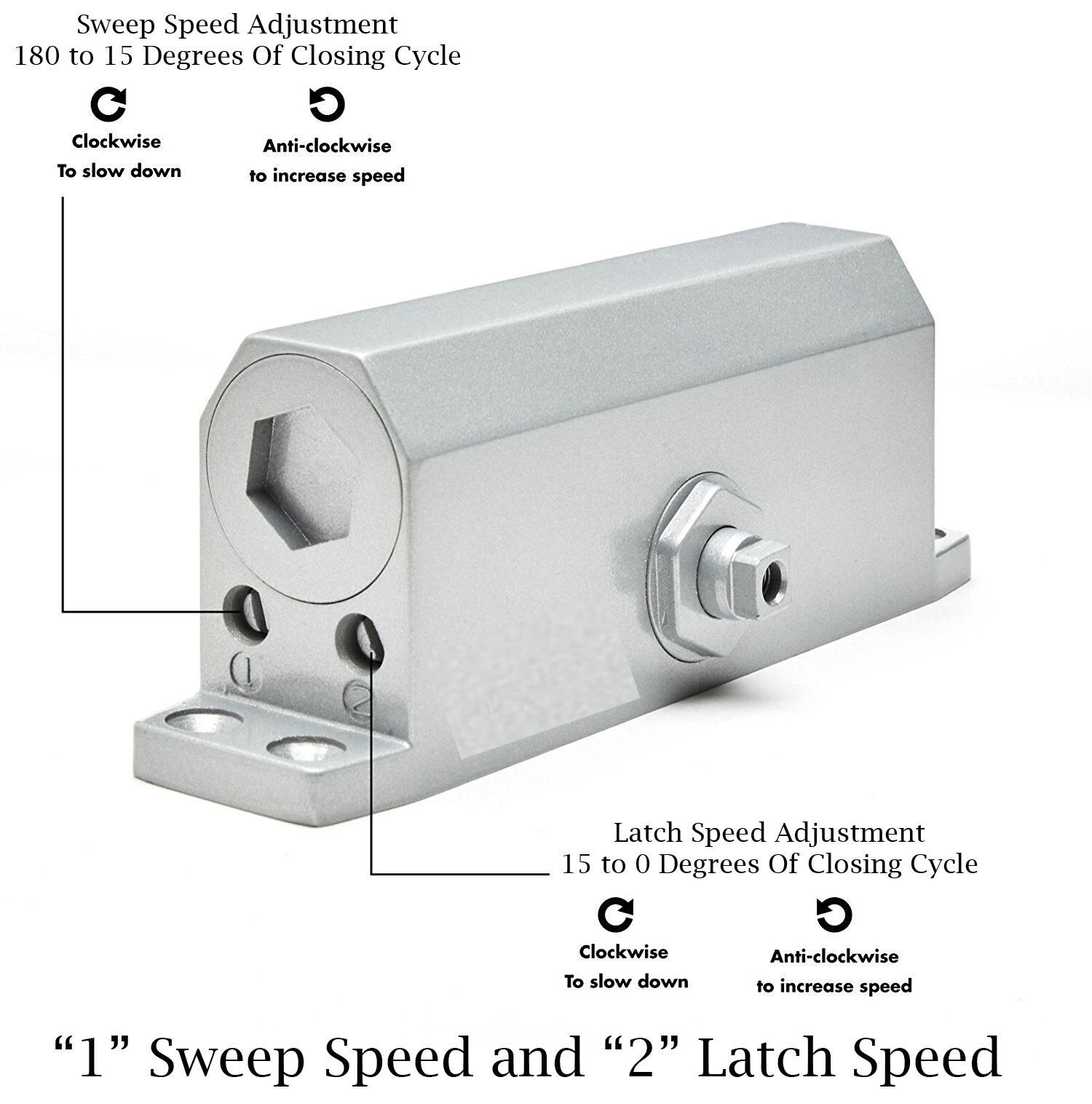

"1" and "2" Are On The Door Closer, Not "S" and "L"

On some door closers the term "S" and "L" are not used, instead a numeric system is used "1" and "2". Where "1" is the sweep speed adjustment valve and "2" is the latching speed valve adjustment.

![]()

S and L Valve Adjustments

To increase the "S" (sweep) or "L" (latch) speeds, the valves can be turned clockwise to increase speed, and counter-clockwise to decrease speed. It is always recommended that when making adjustments only turn the valves 1/8 to 1/4 turn at a time. Too many revolutions of the valve can result in the valve completely unscrewing from the closer body, causing all hydraulic pressure to be lost.

ADA and Closing Speed

According to the Americans With Disabilities Act (ADA) standards, section 404.2.8 states that door closers must take atleast 5 seconds to close from 90 degrees to 12 degrees of the closing cycle range. This means that the door closer must take atleast 5 seconds to close during the sweep range. No latch speed is recommended, however it is common practice to make sure that the latch speed is slower than the sweep speed. The latch speed should never slam shut. Doing so, could result in bodily damage as pedestrians could risk getting their fingers smashed when the door slams. Any slamming door is a very dangerous situation and means that the door closer is not adjusted properly.

![]()

Conclusion

S and L are closing speed adjustment valves for a commercial door closer; where "S" indicates the sweep speed valve adjustment and "L" indicates the latch speed valve adjustment. If your door closer valves are faulty or they have been removed and you have lost hydraulic pressure, we recommend the replacing the door closer with a Liberty door closer. Liberty door closers are high quality and designed for installation on any commercial door type: hollow metal, solid core wood, or storefront aluminum.

![]()

DISCLAIMER:INFORMATION PROVIDED THROUGH THIS SITE IS PROVIDED TO YOU AS IS WITHOUT ANY EXPRESS REPRESENTATIONS OR WARRANTIES OF ANY KIND, AND WE MAKE NO REPRESENTATION OR WARRANTY THAT THIS SITE (OR ANY INFORMATION PROVIDED IN RESPONSE TO YOUR INQUIRY), WILL BE ACCURATE, COMPLETE, OR ERROR-FREE.YOU AGREE THAT YOU MUST EVALUATE ALL INFORMATION AND RESPONSES, AND THAT YOU BEAR ALL RISKS ASSOCIATED WITH, THE USE OF THIS SITE, INCLUDING ANY RELIANCE ON THE ACCURACY,COMPLETENESS, OR USEFULNESS OF ANY INFORMATION OR MATERIALS MADE AVAILABLE THROUGH THIS SITE.