Extra Heavy Duty Industrial Grade Door Closer

Industrial Door Closer Features

- Industrial door closer complies with ANSI A156.4, Grade 1, 2 million cycles, UL/ULC listed up to3 hours fire rated

- Industrial door closer is cast steel

- Industrial door closer is non-handed

- Industrial door closer is tri-packed for regular, top jamb and parallel arm installations.

- Industrial door closer spring size is adjustable 1 - 6 sizes

- Industrial door closer features backcheck: Adjustable, hydraulic - providing cushioning and preventing uncontrolledopenings of the door

- Industrial door closer valves are adjustable, independent, non-critical (sweep and latch), consistentclosing speeds

Industrial Door Closer Size Options

The door closer contains a fully adjustable spring allowing the door closer to be installed on any commercial door.

- Size 1 To 6: For Interior Doors 32" To 60" Wide or Exterior Doors 28" To 54" Wide

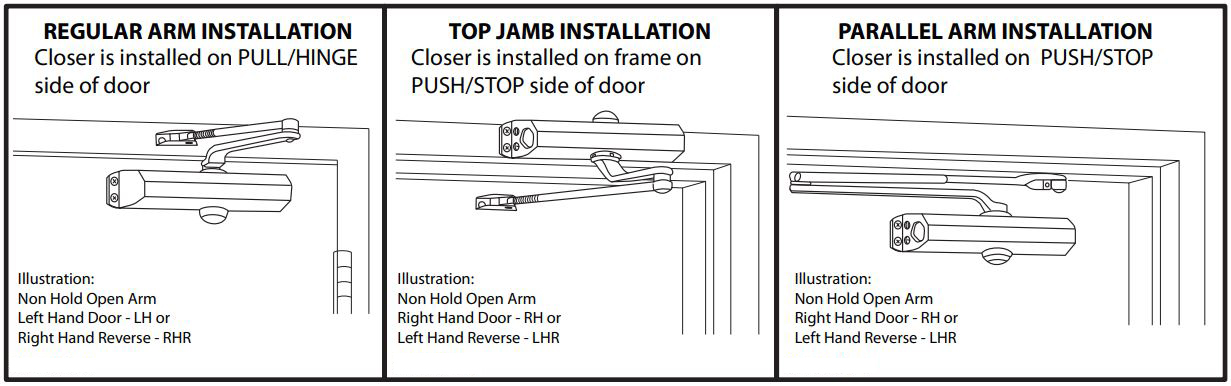

Industrial Door Closer Arm Type Options

- The Industrial Door Closer Is Tri-Packed, meaning it can be installed Regular, Top Jamb, or Parallel Arm

![]()

Industrial Door Closer Drop Plate Option

A flat drop plate option is available for installations where there is low headroom or insufficient mounting space on the door frame.

Industrial Door Closer Regular Arm Installation With Drop Plate

![]()

Industrial Door Closer Top Jamb Installation With Drop Plate

![]()

Industrial Door Closer Parallel Arm Installation With Drop Plate

![]()

Industrial Door Closer Additional Mounting Hardware

- Sex Nuts and Bolts: Set of 4 Each. For steel door applications.

![]()

Industrial Door Closer Comes Standard With Backcheck

The adjustable back check provides a checking or cushioning effect as the door is severely thrust open, typically as it might be caught by the wind, or in violent egress by an individual. The back check helps prevent damage to the door, door hardware, or to adjacent wall surfaces. The strength of the checking action is adjustable, and when it is fully employed (not recommended) it places considerable strain on the door closer, which can result in failing or leaking. It is always best to turn out back the back check valve 1-1/2 to 2 full turns from the fully closed position for safety

Industrial Door Closer Hold Open Function

This option allows you to add a hold open arm to the door closer. A hold open arm is an adjustable arm that allows the user to set the door to a hold open position.

![]()

Industrial Door Closer Adjustment

IndustrialDoor Closer Closing Cycle

Note: Closing arcs (Close and Latch) are controlled by two (2) separate speed valve adjuster. Adjust the closing speed first, then adjust the latching speed.

1. Closing speed adjustment is accomplished by full rotations of the speed valve adjuster. - Turn the speed valve screw clockwise for a slower close arc closing speed. - Turn the speed valve screw counter-clockwise for a faster close arc closing speed.

2. Latch speed adjustment is accomplished by full rotations of the speed adjuster valve. - Turn the speed valve screw clockwise for a slower latch arc closing speed. - Turn the speed valve screw counter-clockwise for a faster latch arc closing speed.

CAUTION!!! Do not turn speed adjuster valve more than two (2) full turns counter-clockwise from its factory default position, as the two speed valve adjusters could become dislodge from the door closer body, resulting in the loss of internal fluid and failure of the device.