![]()

How To Choose The Right Door Closer

A door closer comes in different spring power sizes, colored finishes, closer body types, door cycle durability, mounting types, and testing certifications. All these factors must be considered in order to purchase the right door closer for your door application. Choosing an incorrect door closer could result in thousands of dollars in damage to your door. For example, an undersized door closer installed on a large commercial door can cause the door closer seals to compromise and leak; as a result the hydraulic fluid or oil from the door closer can leak all over your door, essentially staining and destroying your door. In this article, we go over what you need to know in order to purchase the right door closer for your door so these "door catastrophes" never happen to you.

1. Door Size

A door closer is hydraulic mechanical device used to control the closing swing of a door. They are mainly used on commercial doors but can be found on some residential home doors. Commercial door closers use internal springs that compress when the door is opened and decompress when the door is closing. The spring essentially powers the door closed. The heavier or bigger the door is, the bigger the spring required. Commercial door closers range in spring sizes from 1 being the lightest duty spring up to 6 being the heaviest or largest size spring. For example, a large 48" outswing exterior door would require a spring size of 5, while a small 32" interior door would suffice with a spring size of 1.

If your door is an interior door then the recommended spring sizes are:- 28"-32" interior door would require spring size 1

- 32"-36" interior door would require spring size 2

- 36"-42" interior door would require spring size 3

- 42"-48" interior door would require spring size 4

- 48"-54" interior door would require spring size 5

- 54"-60" interior door would require spring size 6

If your door is an exterior door that swings out then the recommended spring sizes are:- 24-28" Exterior door would require spring size 1

- 28"-32" Exterior door would require spring size 2

- 32"-36" Exterior door would require spring size 3

- 36"-42" Exterior door would require spring size 4

- 42"-48" Exterior door would require spring size 5

- 48"-54" Exterior door would require spring size 6

If your door is an exterior door that swings in then the recommended spring sizes are:- 24" Exterior door would require spring size 1

- 24"-28" Exterior door would require spring size 2

- 28"-32" Exterior door would require spring size 3

- 32"-36" Exterior door would require spring size 4

- 36"-42" Exterior door would require spring size 5

- 42"-48" Exterior door would require spring size 6

![]()

2. Door Closer Mounting

Commercial door closers can mount in 3 ways: standard, top jamb, and parallel arm. Each method provides it's own benefits. When choosing which method you plan to mount the door closer always consider the space around your door. For example, if you have an exit sign directly above your door frame, then the standard mount or parallel arm mount would be a better choice than the top jamb mount.

Standard Mount (Pull Side of Door)The most common door closer mounting method is standard mount or sometimes referred to as regular mount. The main advantage of the standard mount is that the door closer body mounts to the pull side of the door. This allows for less space on the door's top rail than the parallel arm mounting method. Due to the physics of the door closer placement, the standard mount also allows for the maximum door closer power. Standard mount installation also allows for the door to swing 180 degrees. All standard mount door closer installation are for interior doors only and not for exterior doors.

Top Jamb Mount (Push Side of Door)Top jamb mounting is the best choice for exterior doors such as aluminum storefront entrance doors. The main advantage of the top jamb mount method is that it can handle large reveals. It also allows the door to swing 180 degrees just like the standard mounting method. Unlike the standard mounting method, the top jamb mounting is designed for the door closer body to be installed on the push side of the head of the door frame. This makes top jamb mounts ideal for any commercial storefront doors which are exterior doors and typically have a narrow top rail. The only real disadvantage of the top jamb mount method is that space is required above the door frame.

Parallel Arm Mount (Push Side of Door)The parallel arm mounting method is ideal for installations where there is no space on the door frame face. The door closer mounts to the push side of the door and the door closer forearm mounts to the underside of the door frame soffit with a soffit plate, commonly known as a parallel arm bracket. No space is required on the door frame face. Parallel arm mounting methods are very common on hollow metal and commercial wood doors. When considering a parallel arm installation the depth of the door's top rail must be considered as that is where the door closer body mounts. One benefit of the parallel arm mounting method is that the arm does not stick out as far past the door as the standard or top jamb mounting methods; allowing the chances of any kind of tampering to be much less. There are some disadvantages of the parallel arm mounting method and that is the physics. Due to the positioning of the arm and door closer, parallel arm mounted door closers are bout 25% to 30% less powerful than standard mounted door closers. Another disadvantage of the parallel arm mount method is that the door closer requires the extra parallel arm bracket, which is an additional cost.

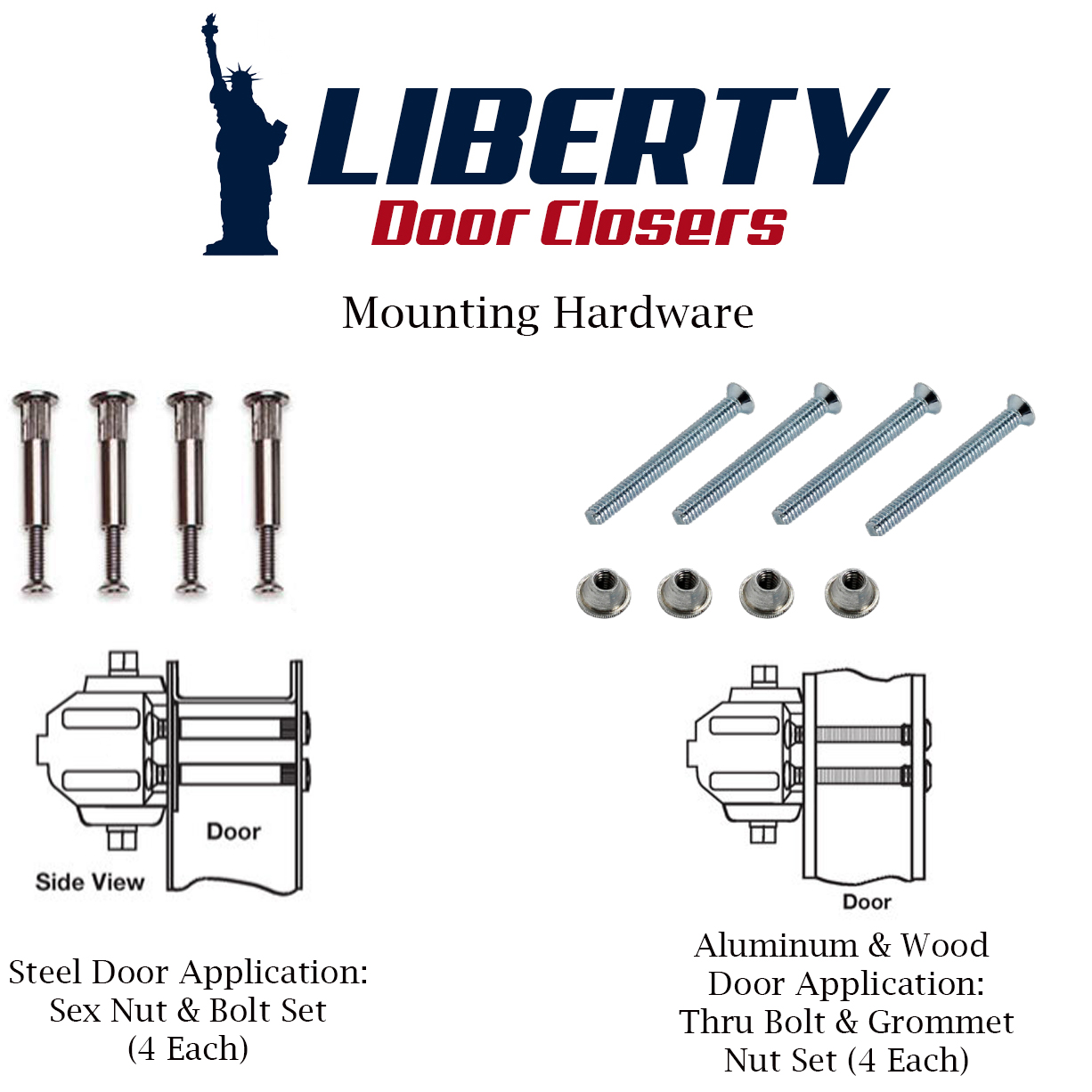

![]() Door Closer Hardware

Door Closer HardwareAs a generality if the door material is metal such as commercial hollow metal door, then sex nuts and bolts should be used and if the door is constructed of wood or aluminum then thru bolts and grommets can be used.

![]()

3. Door Closer Functions

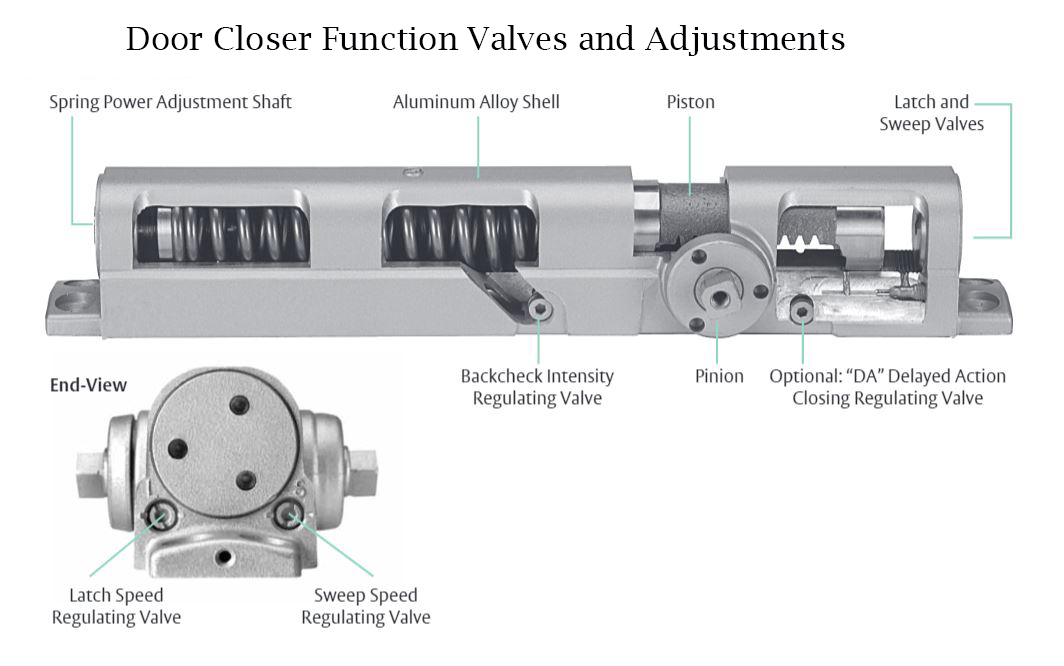

All commercial door closers include two basic valve speed adjustments on the door closer body:

Closing Speed Valve: This is the main speed valve that controls the speed of the door closing up until the last 10 to 12 degrees.

Latch Speed Valve: This is the secondary speed valve that controls the speed of the door closing the last 10 to 12 degrees.

There are two other door closer functions which typically are an additional cost. However, they offer an immense benefit to the overall performance of the door closer. These optional adjustments are:

Backcheck Speed Valve: This valve controls the speed of the door opening beginning at around 75 degrees. Why is this optional function useful? Backcheck is commonly referred to as the cushion, and that is because if the door is swung abruptly open, when the door reaches 75 degrees open the door will enter back check speed. The back check speed can essentially save your door from slamming open due to abusive pedestrians or strong wind storms.

Delayed Action Valve: This valve is sometimes referred to as the hold open adjustment. When the door is fully open and is about ready to begin closing, the door goes into the delayed action speed. The delayed action speed lasts from the point of the door being full open in the closing cycle to the point that the door reaches about 70 degrees of the closing cycle. The delayed action speed valve can be adjusted to keep the door remaining open for up to 30 seconds. The delayed action valve is a great option for doors in nursing homes, schools, or hospitals where the elderly, children, or pedestrians with disabilities are present.

![]()

4. Door Closer Fire Rating

According to the National Fire Protection Agency (NFPA 80), fire doors must be self closing, automatic closing, or power operated. The door closer device must be listed as UL10c for fire protection. You can easily check if your door is a fire door by opening the door and looking for a fire label on the hinge side of the door. See illustration below for an example of a fire rated door. If the door is fire rated, the door closer must be UL10c listed. Another consideration is to always use the proper hardware when mounting the door closer to the fire door. A fire door will have a plate within the door for reinforcement. The hardware provided by the door manufacturer should always be used. All Liberty door closers are UL10c listed for installation on fire rated doors.

![]()

5. Door Closer Usage

The frequency that the door is used should always be considered. As common sense tells us, a storeroom door would not be opened as much as the same building's front entry doors. Door closer grades are listed to help identify how heavy duty a door closer is. A door closer is given a grade based on how many cycles that particular door closer completed.

Grade 1 Door Closers: Tested For 2 Million Door Cycles

Grade 2 Door Closers: Tested For 1 Million Door Cycles

Grade 3 Door Closers: Tested For 500K Door Cycles![]()

6. ADA Compliance

According to the Americans With Disabilities Act (A.D.A) a door closer must only require 5lb of continuous opening force until the door is in the full open position. It also states that the door must close from 90 degrees full open to 12 degrees in atleast 5 seconds. If the door closes too fast it will not meet ADA compliance. Choosing an adjustable spring door closer, will allow the installer to adjust the spring size appropriate for the door to allow for a proper closing speed. Remember the closing speed can also be adjusted with the main closing speed valve, but that is assuming the spring size is correct for the door size. Barrier free door closers are also available which only allow for a 5 lb opening force.

![]()

Our Recommendation

We recommend the

Liberty Rockwell Door Closer for ADA compliance as it features a 5lb opening force and a fully adjustable spring. It is also a grade 1 door closer, so it has been tested to last more than 2 million door cycles, the highest available grade in the door industry. The Rockwell door closer by Liberty Door Closers also comes tri-packed, so it can be installed in all three ways: standard mounting, top jamb mounting, parallel arm mounting.

![]()

DISCLAIMER:INFORMATION PROVIDED THROUGH THIS SITE IS PROVIDED TO YOU AS IS WITHOUT ANY EXPRESS REPRESENTATIONS OR WARRANTIES OF ANY KIND, AND WE MAKE NO REPRESENTATION OR WARRANTY THAT THIS SITE(OR ANY INFORMATION PROVIDED IN RESPONSE TO YOUR INQUIRY), WILL BE ACCURATE, COMPLETE, OR ERROR-FREE.YOU AGREE THAT YOU MUST EVALUATE ALL INFORMATION AND RESPONSES, AND THAT YOU BEAR ALL RISKS ASSOCIATED WITH, THE USE OF THIS SITE, INCLUDING ANY RELIANCE ON THE ACCURACY,COMPLETENESS, OR USEFULNESS OF ANY INFORMATION OR MATERIALS MADE AVAILABLE THROUGH THIS SITE.